The SCORPIO-VVER Core Monitoring and Operation Support System represent an online reactor core surveillance system for continuous core monitoring and control of core characteristics.

The SCORPIO-VVER system uses the on-line plant measurements without an impact to the technology. It provides continuous monitoring of the core, evaluations of the principal core characteristics based on measurement data and results of on-line simulation, and control of Core Technical Specifications, which are significantly improves the plant operation safety and allow reliable, flexible and efficient plant operation.

Since it’s first installation, the development of SCORPIO-VVER system continues along with the changes in VVER reactors operation. The system is being adapted according the utility needs. With its flexible and modular framework it successfully responses to the plant operating needs and advances in nuclear fuel cycle strategies and fuel design.

Modular framework allows for easy modifications of the system and implementation of new methods in the individual modules. These facts have been confirmed by successful upgrades and more than 12 years of reliable operation of the core monitoring system.

The Supplier and the Service organization of the SCORPIO-VVER core monitoring system is the Nuclear Research Institute Rez.

The SCORPIO-VVER Core Monitoring and Operation Support System, as it is operated at Dukovany NPP in Czech Republic and Bohunice NPP in Slovak Republic, has been developed from the original SCORPIO system framework in cooperation among Norwegian IFE Halden (HRP) and Czech organizations Nuclear Research Institute Rez plc., Skoda JS, a.s., Chemcomex Praha, a.s. and the Slovakian VUJE, a.s. The system has remarkable operating records from its first introduction to Dukovany Unit-1 in 1998 replacing the original Russian VK3 system. It has been installed in other 5 VVER-440/V213 units and it was licensed by national nuclear regulatory bodies in Czech Republic in 1999 and in Slovak Republic in 2002 as a Technical Specification Surveillance Tool.

The SCORPIO-VVER core monitoring system is subject of regular upgrades, which serves to system improvements and modifications according to utility needs and the development team proposals too.

The original SCORPIO system has been in operation at the Ringhals PWR unit 2 in Sweden since the end of 1987. In addition, the system has been installed at Nuclear Electric's Sizewell B PWR in UK and all the 7 NPPs of Duke Power Co. in USA. Special version of SCORPIO for BWR type of reactors are is in operation since 2002 in JAPAN.

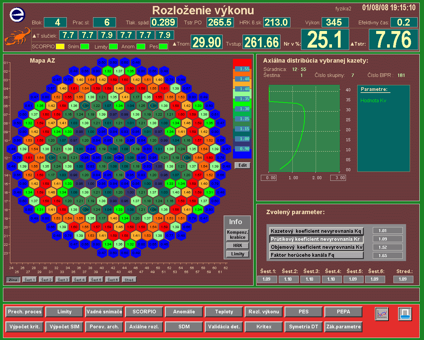

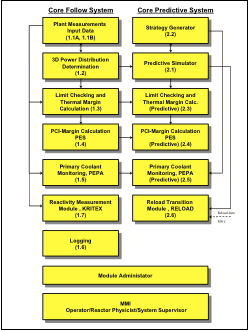

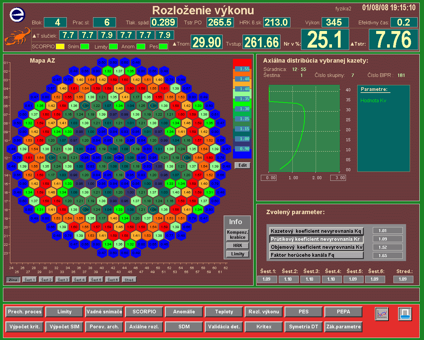

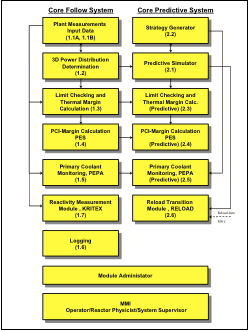

The SCORPIO-VVER Core Monitoring System consists of autonomous modules, which communicate through the communication package Software Bus. The main modules in SCORPIO-VVER are identified in the block diagram shown in Figure below. The Man-Machine Interface is developed using the ProcSee GUI Management System. The system is running in full redundancy configuration on HP PA-RISC workstations using HP-UX OS.

The system support different user logins with different levels of rights and information details. The SCORPIO-VVER operates in two modes: in core follow mode and in predictive mode.

In the core follow mode, the present core state is evaluated by a method combining the instrumentation signals and the theoretical calculation of the power distribution done by the core simulator, which is based on the universal finite-difference program MOBY-DICK [6]. This procedure, called 3D power reconstruction, is followed by an automatic limit checking, where characteristics of the current state are compared to the Technical Specifications. The operator obtains relevant information on core status through the Man-Machine Interface (MMI) in the form of well arranged screens containing trend curves, core map pictures, diagrams and tables displaying relevant information on the core state including margins to Technical Specifications.

In the predictive mode, the operator can visualize the core characteristics during the transients forecasted for coming hours or days. Quick forecasts realized by the strategy generator are deeply analyzed by the predictive simulator. As no detector signals are available in this case, the accuracy of the predicted core state depends heavily on the quality of the physics model. Similarly as in the core follow mode, characteristics of the evaluated states can be compared against Technical Specifications, and the predicted behaviour of the core can be analyzed through the number of dedicated screens.

The SCORPIO-VVER system includes following main features:

- Maintaining the redundant communication with plant data sources, collection of input data from the measurement circuits.

- Validation of plant measurements and identification of sensor failures.

- Temperature measurement sensor calibration, evaluation of isothermal state.

- Enhanced with a tuned/weighted combination of measurements and calculations to obtain precise values of important parameters.

- On-line 3D power distribution calculation with pin power reconstruction, based on the validated outlet temperature from thermocouples, SPND measurements and from the results of on-line core simulator.

- On-line core simulation based on two-group 3D coarse mesh calculation code (modified version of licensed Moby-Dick code).

- Limit checking and thermal margin calculation allowing for surveillance of VVER core limits such as DNBR, Sub-cooling margin, FdH and other peeking factors, etc.

- SPND monitoring, evaluation, interpretation and transformation to linear power.

- Integrated modules for monitoring fuel performance, conditional power distribution and PCI monitoring.

- Integrated modules for monitoring of coolant activity for identification of fuel failures.

- Predictive capabilities, strategy planning and boron batching optimization, offering the possibility to check the consequences of operational manoeuvres in advance, prediction of critical parameters and end of fuel cycle detection, main steam-header pressure driving, etc.

- Convenient monitoring and prediction of approach to criticality during reactor start-up (boron dilution, control assembly withdrawal).

- Automated transition between cycles - fuel reload.

- Logging functions with archive for all calculated and main measured data.

- User definable printer output for protocols and forms.

Since the first installation the SCORPIO-VVER system has a remarkable operating history and experience. More than 12 years of experiences from 6 units of VVER-440 type of reactors, from two different NPPs, in two different countries helps the SCORPIO-VVER developer team to put the system to a very high level of quality and reliability.

The system was enhanced and adjusted to fulfill all requirements of NPP operators and to fulfill all operating rules and conditions defined by the State Office for Nuclear Safety in each country.

The system developer team is ready to respond to all needs of the NPP’s, solve the difficulties and answer all questions in local language of NPP operators. All system documentations and user guides are maintained in 3 different languages: English, Czech and Slovak.

Our partners and customers are given access to the support center, where they can find support for our software products (user guides, updates, issue solutions). If you don't have access information, please ask for them via

e-mail.

Support center access